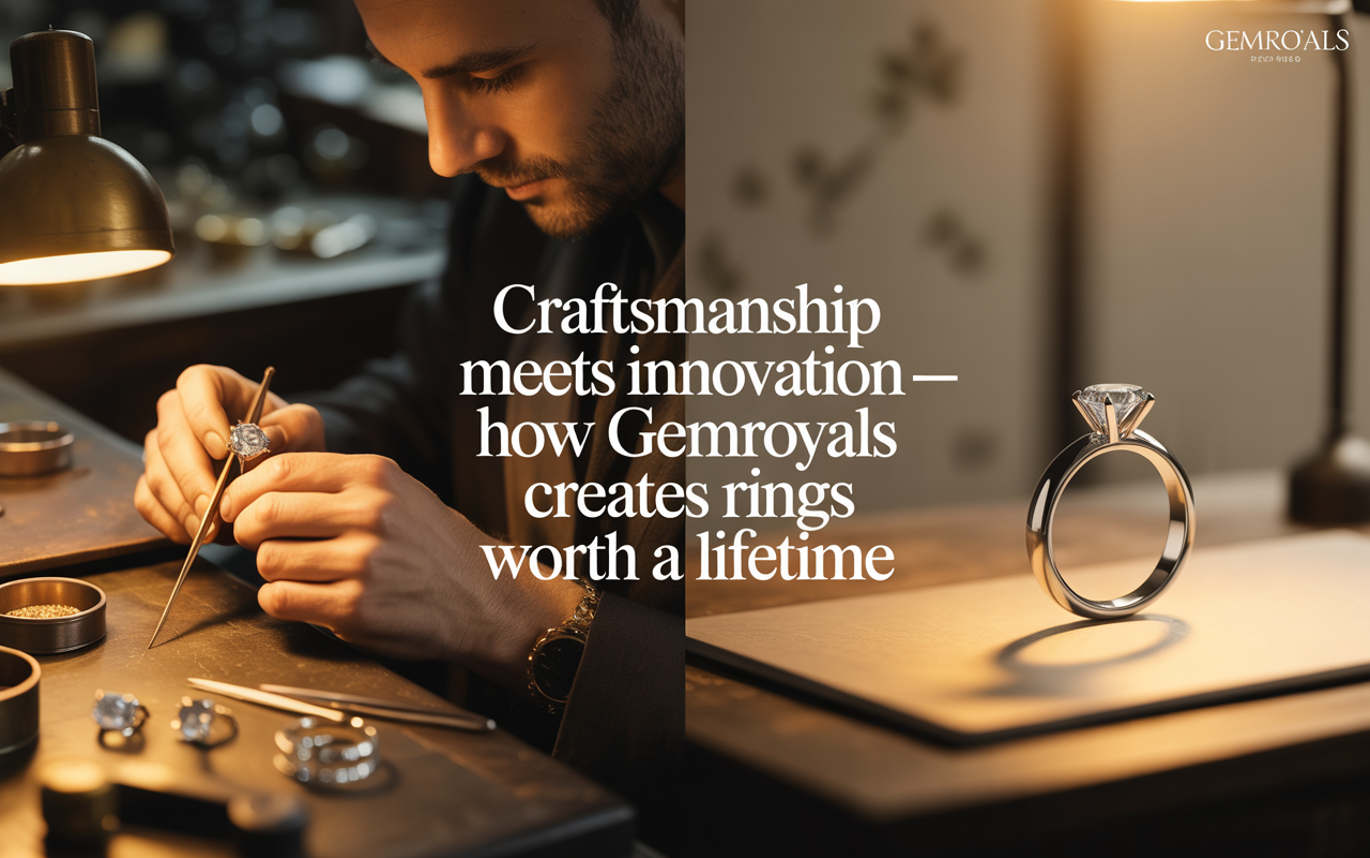

In a world where jewelry can be mass-produced in minutes, true craftsmanship has become a rare commodity. At Gemroyals, it’s not just preserved — it’s celebrated. Every ring the brand creates is a blend of human artistry and cutting-edge technology, designed to endure as long as the love stories it represents.

From concept sketches to the final polish, the Gemroyals design process reflects a commitment to perfection that goes far beyond industry standards. Here’s a rare behind-the-scenes look at how the brand transforms raw materials into rings worthy of a lifetime.

The Philosophy: Perfection Without Compromise

For Gemroyals, a diamond ring is not simply a product — it’s a milestone marker. Whether it’s an engagement, wedding, or anniversary, the piece will hold meaning for decades. That’s why the brand refuses to cut corners in its design process.

“A ring should look just as beautiful on your 25th anniversary as it did on the day you first wore it,” says the Gemroyals founder. “That’s only possible when every stage of the process is handled with care.”

This philosophy guides everything from the initial sketch to the final inspection.

Step 1: The Spark of Inspiration

Every Gemroyals design starts with inspiration — sometimes drawn from timeless silhouettes, sometimes sparked by customer ideas. The design team studies trends, historical pieces, and customer feedback to create engagement rings for women that balance classic elegance with modern appeal.

Rather than jumping straight into software, Gemroyals begins with hand-drawn sketches. This allows for free-flowing creativity before committing to proportions and technical details. It’s a nod to traditional artistry that keeps each design grounded in human touch.

Step 2: Precision Through Technology

Once a sketch is refined, Gemroyals moves into CAD (Computer-Aided Design). This step transforms the design into a precise 3D model, allowing the team to adjust proportions, test durability, and visualize every angle.

CAD ensures that prongs are positioned perfectly, diamond seats are exact, and the ring will be structurally sound for everyday wear. The digital model also allows customers ordering custom designs to preview their ring before production — a reassurance few jewelers offer.

Step 3: Diamond Selection Beyond the 4 Cs

A Gemroyals diamond is chosen with far more scrutiny than standard grading charts require. Yes, the 4 Cs — cut, color, clarity, and carat — are considered, but the brand goes further:

- Light Performance — How the stone sparkles in natural sunlight, warm indoor light, and LED light.

- Symmetry & Polish — Precision in facet alignment for optimal brilliance.

- Fluorescence Evaluation — Ensuring the diamond’s glow doesn’t compromise clarity or color.

Whether natural, lab-grown, or moissanite, every stone is inspected under magnification and hand-selected by Gemroyals in-house experts.

Step 4: Casting & Metalwork

The ring’s foundation begins with high-quality metal — 14k or 18k gold in yellow, white, or rose, or platinum for those seeking premium durability. Gemroyals often uses recycled precious metals, aligning with the brand’s sustainability values.

The base structure is cast using modern techniques for precision, but shaping, smoothing, and fine adjustments are done by hand. This is where craftsmanship transforms a cold cast into something truly elegant.

Step 5: Stone Setting — The Heart of the Craft

Stone setting is one of the most delicate and skilled parts of jewelry making. Gemroyals master setters work under microscopes, securing each diamond with perfect alignment and minimal visible metal.

Whether it’s a classic four-prong solitaire, a pavé band, or a halo design, the goal is always the same: maximum sparkle, structural security, and perfect symmetry. Even the smallest accent stones are placed with the same care as the center diamond.

“Machines give us accuracy, but only hands can give life to a ring,” says the founder.

Step 6: The Finishing Touches

After setting, the ring is polished multiple times to achieve a flawless surface. Any sharp edges are softened for comfort, and the band is checked for perfect roundness. Gemroyals also offers engraving services, allowing customers to inscribe dates, initials, or personal messages.

If the design includes intricate details like milgrain edges or hand-engraved patterns, these are added at this stage by skilled artisans — ensuring no two rings are exactly alike.

Step 7: Rigorous Quality Control

Before a ring is shipped, it undergoes Gemroyals multi-point inspection:

- Visual Perfection — Checking symmetry, polish, and finish.

- Stone Security — Ensuring no stones are loose or misaligned.

- Comfort Fit — Making sure the ring sits perfectly on the finger.

- Certification Check — Verifying that grading reports match the actual product.

Only after passing these checks does the ring receive the Gemroyals seal of approval.

Customization: Making It Truly Yours

One of Gemroyals greatest strengths is its ability to create fully customized designs. Couples can request unique combinations of diamond shapes, mixed metals, personalized gallery designs, or hidden birthstones under the setting.

This bespoke approach means the final piece reflects the couple’s story — whether that’s a nod to a shared hobby, a hidden symbol of their initials, or a recreation of a vintage family heirloom.

Balancing Tradition and Modern Innovation

What makes Gemroyals stand out is its blend of old-world craftsmanship and 21st-century technology. CAD design, precision casting, and high-resolution previews give accuracy, while skilled artisans infuse warmth, soul, and individuality into each piece.

The result is a ring that feels as personal as it is precise.

Why Craftsmanship Still Matters

In a fast-paced, mass-production world, quality craftsmanship ensures a ring can be worn every day for decades without losing beauty or structural integrity. It’s what allows Gemroyals customers to pass their rings down as heirlooms — rings that carry not just diamonds, but stories.

“Jewelry should last longer than trends,” says the founder. “We’re not just making rings — we’re making memories that survive generations.”

Looking Ahead: Crafting the Future

As Gemroyals grows, the brand plans to share more of its behind-the-scenes process with customers — from design videos to artisan interviews. The goal is to give couples an even deeper connection to the craftsmanship behind their ring.

In a market where many see jewelry as a commodity, Gemroyals continues to prove that the magic lies in the making— and that the right combination of skill, technology, and passion can create rings truly worth a lifetime.